What is 48V/Balmy Hybrid drive applied science?

Lower fuel consumption and emissions with like shooting fish in a barrel implementation in existing vehicle platforms: That’s what makes 48V mild hybrids then interesting in the transition stage to due east-mobility. On this folio, you tin learn all about this technology, which is currently spreading across a wide range of manufacturers and vehicle classes.

Balmy hybridization: Overview of functions, benefits and fields of

Mild hybridization – A brief overview: What makes a machine a mild

Mild hybrids make conventional combustion engines significantly more than efficient with piffling effort. This involves recovering kinetic energy while the vehicle is braking (“recuperation”) – but like KERS in Formula 1.

This energy, otherwise lost, is stored in a 48V bombardment and and so used to support the engine and ability a high-functioning 48V on-board electrical system. In addition to other benefits, this mild hybridization cuts fuel consumption by 15% or more – and thus reduces CO2

emissions accordingly.

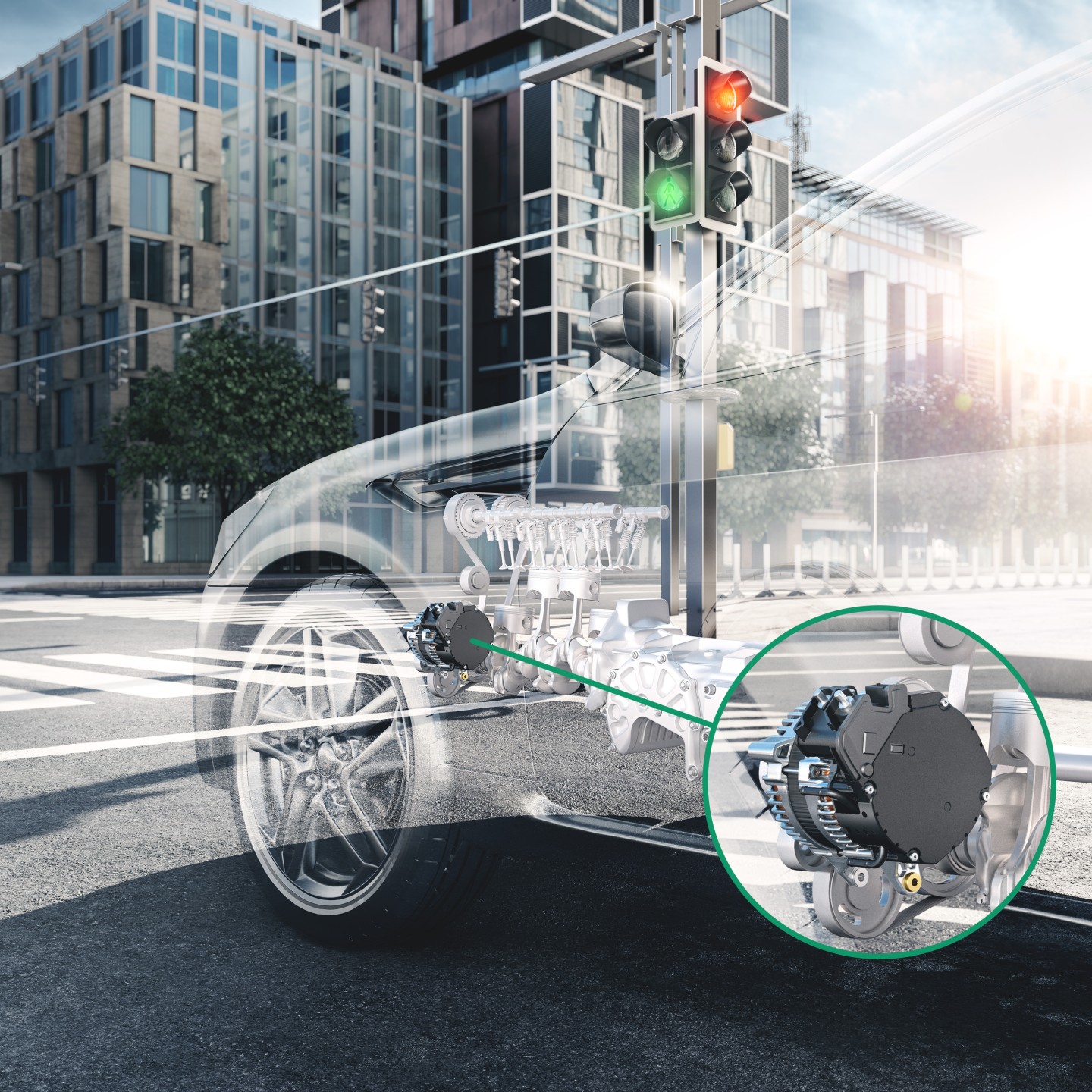

In the simplest implementation (“P0 topology”), the conventional 12V generator is replaced in its integration space on the belt by a 48V machine – a Boost Recuperation Auto, for instance. It converts kinetic energy into electrical free energy with high efficiency during braking and stores it in a small, boosted 48V bombardment. Information technology also supports the combustion engine with up to 12 kW of electrical power. In improver, safety-relevant loftier-operation consumers such as commuter help functions or electric brake boosters tin can exist reliably supplied with 48V voltage.

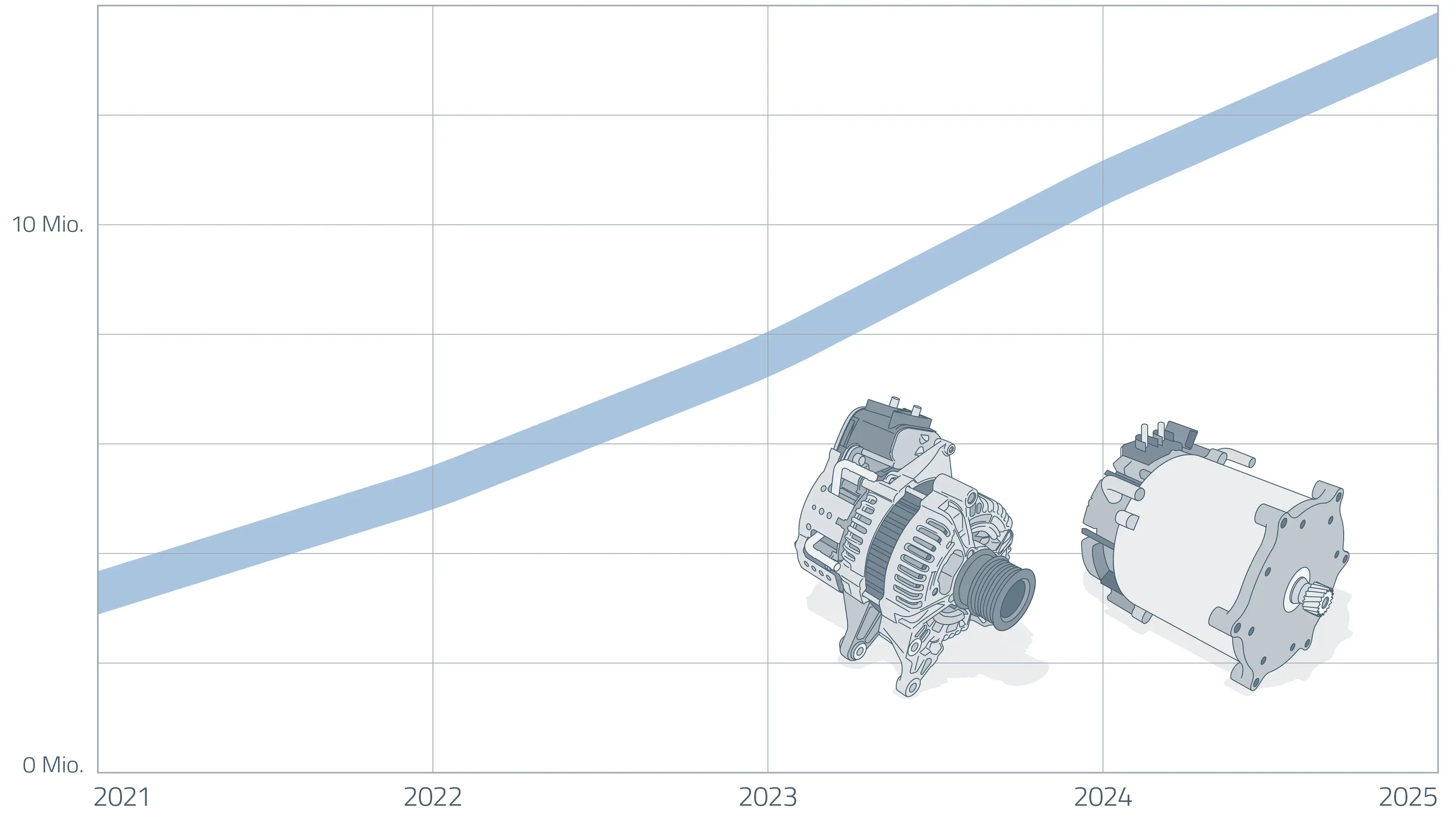

A 48V machine can also be flexibly implemented at other positions in the powertrain – with varying degrees of integration effort and savings potential. To achieve the varying climate objectives in each region, mild hybrids are a vital component for motorcar manufacturers. The technology is showing up in an increasing number of models and vehicle classes. Over 4,five meg vehicles have been equipped with a 48V machine already, primarily with P0 topology. Market research company IHS Markit expects global annual production of 48V mild hybrids to exist well over 10 Million as early as 2025.

Annual 48V hybrid production forecast (source: IHS Markit, https://ihsmarkit.com)

What makes a car a balmy hybrid, and what does 48V stand

A balmy hybrid refers to a vehicle with an internal combustion engine that is besides supported by a small electric drive. The electric motor recovers braking energy (“recuperation”) and makes it available later equally boosted bulldoze power to reduce overall fuel consumption. In contrast to a full hybrid or an electrical machine, a mild hybrid can exist driven in purely electric mode merely to a limited extent.

There are also some mild hybrids operating on 12V. In almost cases, therefore, a more than powerful 48V machine is used, which recuperates more than energy and thus besides reduces fuel consumption to a greater extent. Experts, therefore, often use the terms “mild hybrid” and “48V” interchangeably.

Why exercise we need mild hybrids at

This applied science offers many benefits for drivers and manufacturers – at low implementation costs.

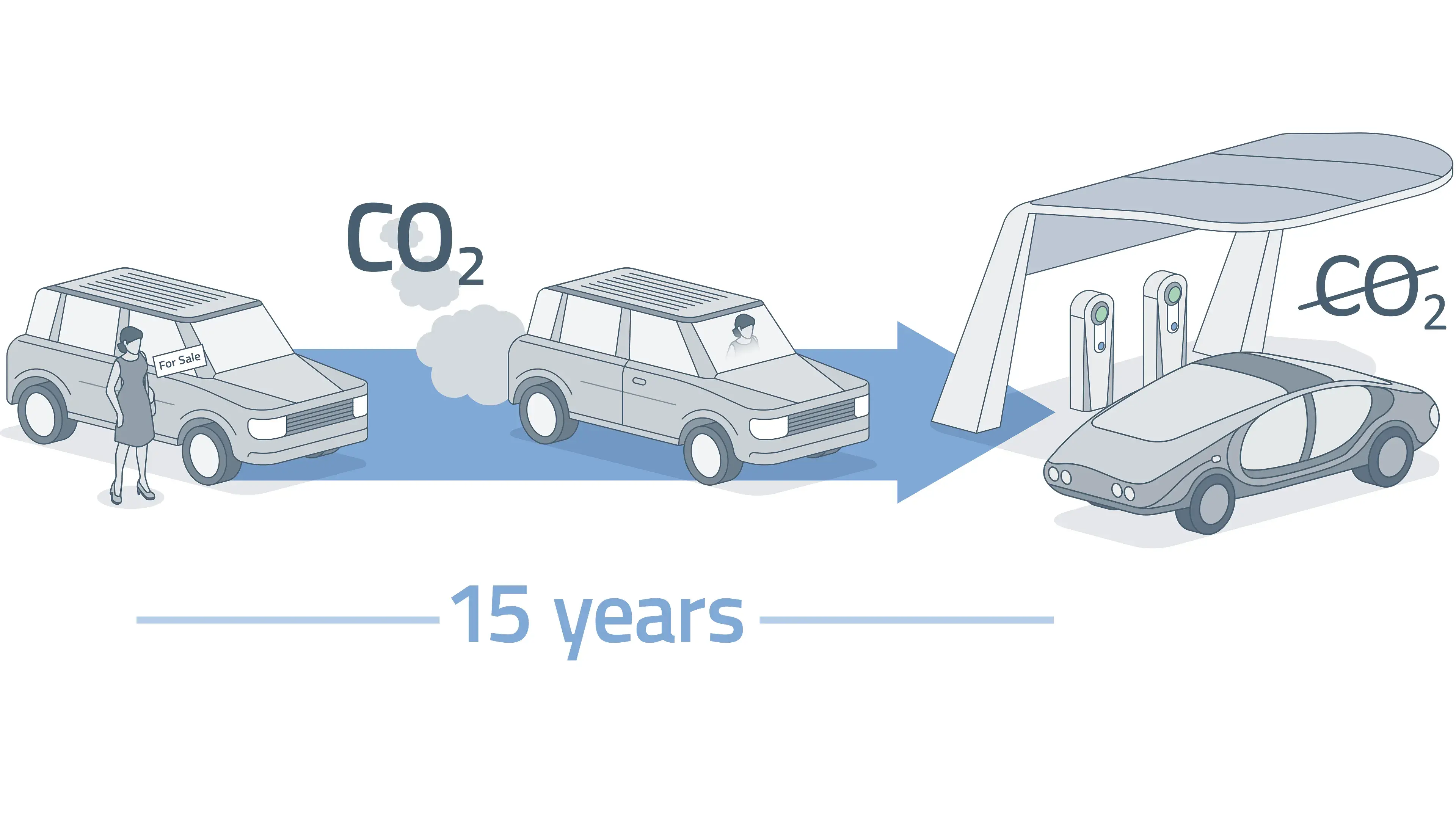

The most important cistron is climate protection, though: e-mobility is emerging, primarily due to the unequivocal political commitment in cadre markets such as Europe and China. Nonetheless, this transformation cannot be accelerated at volition later on all, engineering, battery availability, infrastructure, and power generation must exist further adult simultaneously.

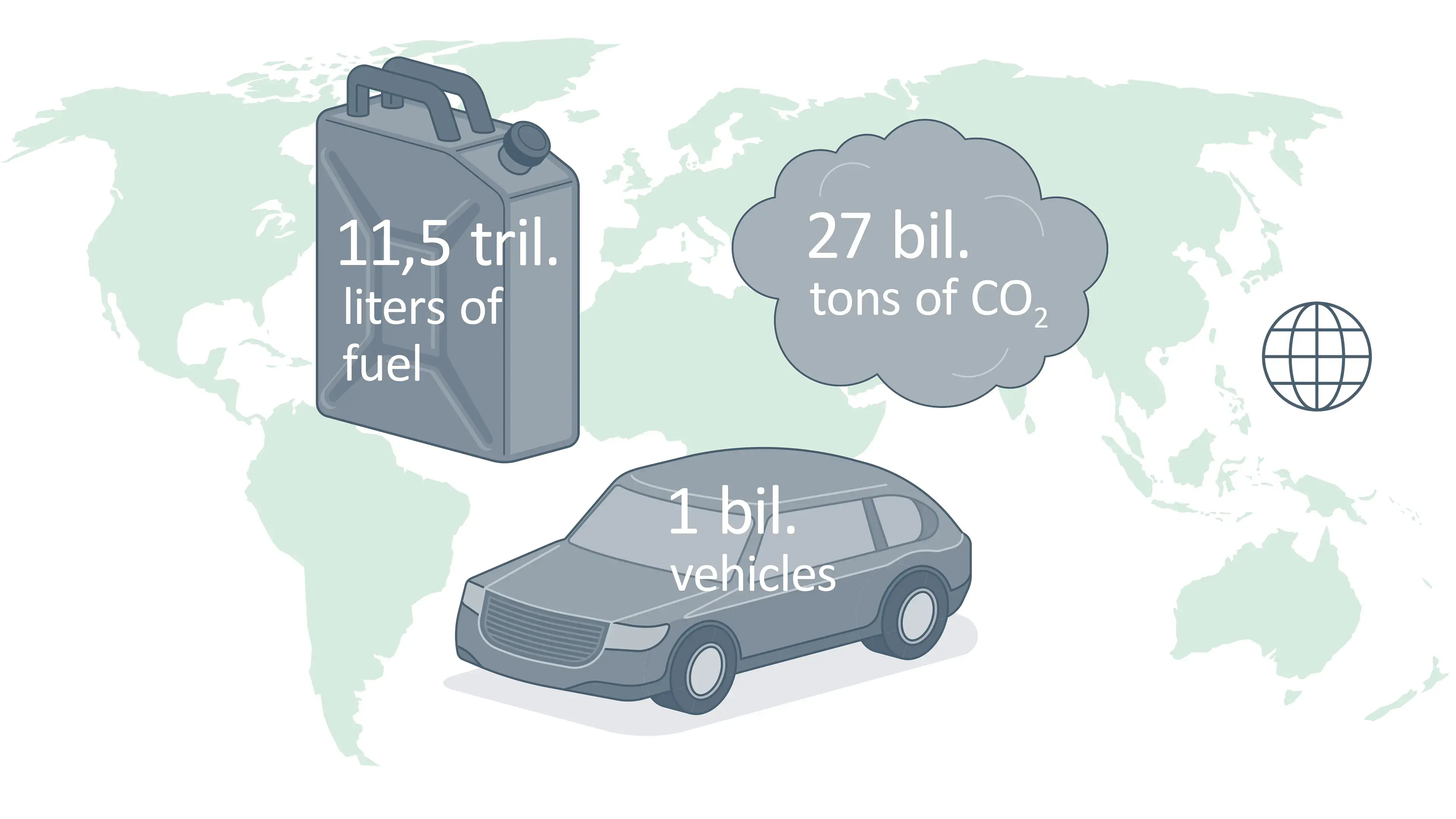

According to the Bloomberg Electric Vehicle Outlook 2021, over 1 billion more cars with internal combustion engines (ICE) are expected to be built by 2040 alone. This is partly due to the much slower shift to east-mobility in regions such as Africa, Latin America and India.

These hereafter Water ice cars would cause up to another 27 billion tons of CO2

emissions – virtually 10% of the global CO2

remainder budget to meet the one.5-degree target.

These vehicles must be designed to be as efficient as possible to minimize global climatic change. Mild hybridization tin forestall 15%-25% of these emissions. Neglecting this technology would hateful losing this savings potential forever.

Equipping all i billion combustion vehicles to be produced by 2040 with 48V hybridization would save at least two billion metric tons of CO2

– around 3 times Federal republic of germany’s total greenhouse gas emissions in 2020. With more complex topologies, savings of four billion metric tons and more are possible through 48V hybridization.

What are the benefits for the

“Upgrading” from a conventional combustion engine to a 48V mild hybrid earns the commuter a meaning increment in the performance range. For example, with a 48V Boost Recuperation Machine braking free energy is recovered while driving with up to 15 kW / 20hp to then support the engine with up to 12 kW/ 16 hp when power requirements increase (boost). It can also eliminate the turbo lag at low engine speeds.

The vehicle can start particularly smoothly and quietly thank you to the 48V engine, and high-consumption comfort. “Coasting” – i.e. driving with the engine switched off at high speeds – becomes possible and can relieve additional fuel.

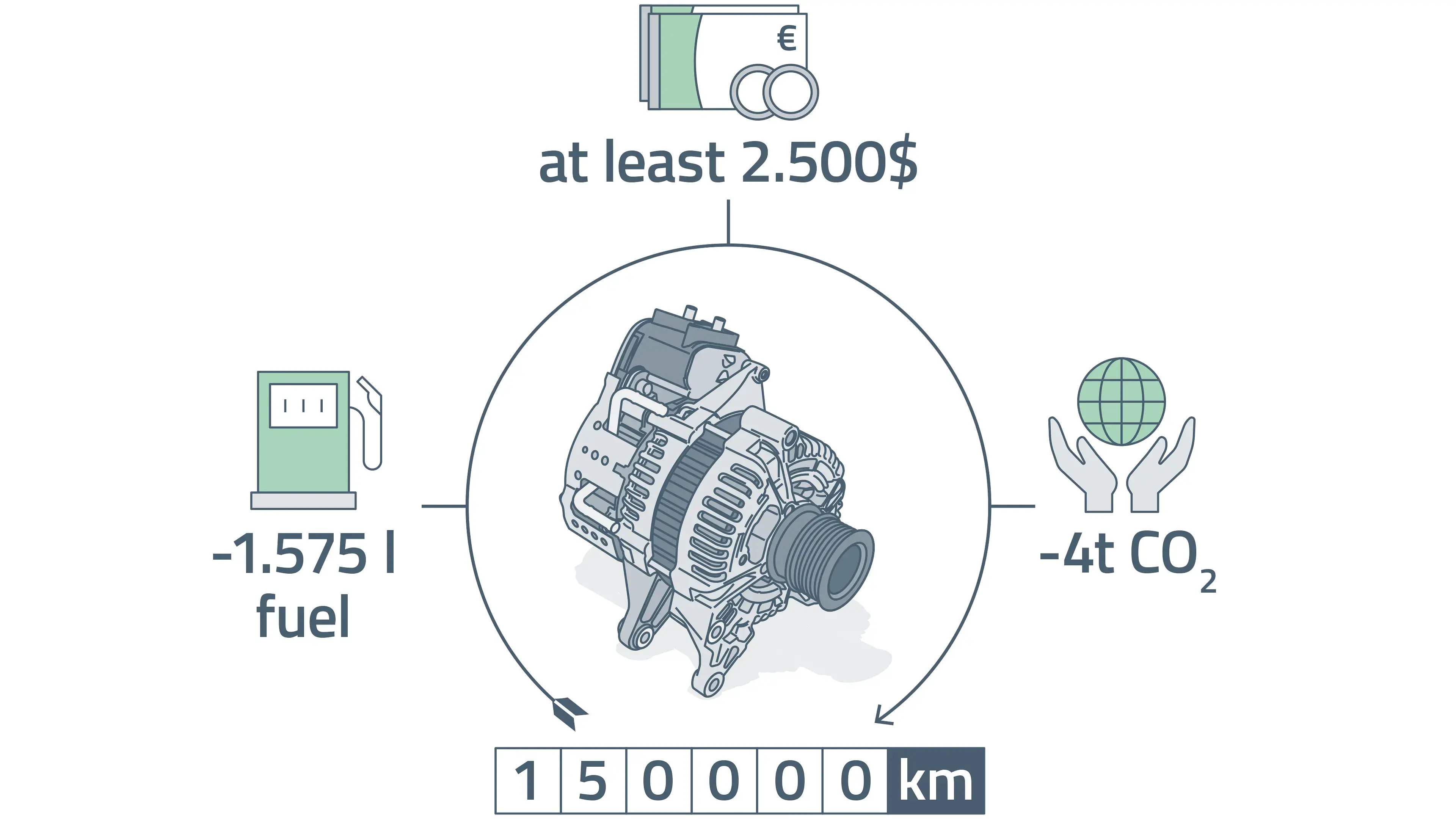

Cheers to significantly reduced consumption, mild hybrids are a ameliorate solution not but for the environment, but also for the driver’s budget: Over a lifetime of 150,000 km, for example, the 48V Boost Recuperation Car saves over 1,500 liters of fuel compared with a conventional combustion engine. This translates into around four tons less CO2 emissions and at least € ii,000 less spent at the gas station.

An electrical motorcar is not an option for everyone today. Reasons for this could be a lot of long-distance driving or the lack of a sufficient local charging infrastructure. In this case, 48V hybrids are a practical solution that minimizes the climate burden and makes driving nevertheless more comfortable and safe.

How does mechanical integration in the powertrain

Balmy hybrid technology can be integrated into all existing powertrain architectures for internal combustion engines. Depending on the desired level of performance and COii

savings, the effort ranges from very depression to medium.

Mild hybridization e’er requires installing an eastward-machine with an inverter in the powertrain in addition to the combustion engine. On elevation of that, a small-scale 48V battery (~0.five – 1kWh) is added to feed the 48V on-board electrical arrangement. Lastly, a DC/DC converter supplies the 12V on-lath electrical organisation. On the other hand, the lower voltage makes circuitous and therefore expensive high-voltage protection requirements and cable harnesses unnecessary.

The required e-car tin can exist flexibly installed in the powertrain – on the belt, in the transmission environs, or on the rear axle. The CO2

savings, e-driving capabilities, the integration effort, and the associated system costs all depend on where the 48V machine’s position in the powertrain. This placement is also called “topology”, with the installation positions beingness abbreviated as “P0” to “P4”.

P0: belt integration

is the well-nigh basic solution for mild hybridization. For this, a 48V machine such as the BRM simply replaces the generator in its existing integration space on the belt. Modification of the powertrain compages is minimal – and so are implementation efforts and system costs. Yet, the recuperation of this “starter generator” tin already reduce fuel consumption by up to 15% in real-world functioning compared to a conventional combustion engine.

P1: betwixt the combustion engine and the transmission

Even so, this is rarely used in practice, as implementation here is more circuitous and plush than with P0, without leveraging farther savings potential to a great extent.

P2 /

P3: transmission setting

P2 indicates an integration directly on the side of the primary transmission or continued via a chugalug, P3 describes the position direct behind it on the drive shaft. Both topologies feature a comparable cost/do good ratio. However, they are mechanically much more complex than P0. For case, the due east-motor needs to be installed in the transmission not as a whole merely as private components, and air cooling is not possible. In addition, a starter motor is normally yet needed in this setup, which as well drives upward costs.

In return, higher savings of upward to 22% can be realized due to lower frictional losses in the engine. Tedious, purely electric driving (“pitter-patter/clamber mode”), e.thou. when parking or during stop-and-go in traffic jams, is technically possible as well.

P4: rear axle

Integration of one or two 48V machines on the rear axle via a differential gear. Frictional losses in the powertrain are lowest here, assuasive for the highest savings (up to 25%). In improver, this topology offers the most comprehensive east-driving functions. Besides the “creep/crawl mode”, a (temporary) all-bike drive could be enabled in conjunction with the combustion engine. This solution represents the most extensive modification of the powertrain and entails the highest organization costs. In this case, an additional starter or starter-generator is as well still necessary.

On the other hand, with the appropriate transmission ratio and power of the e-motor, P4 topology tin also be used to bulldoze 48V full hybrids or even compact 48V electric vehicles – without the safe architecture otherwise required for high-voltage.

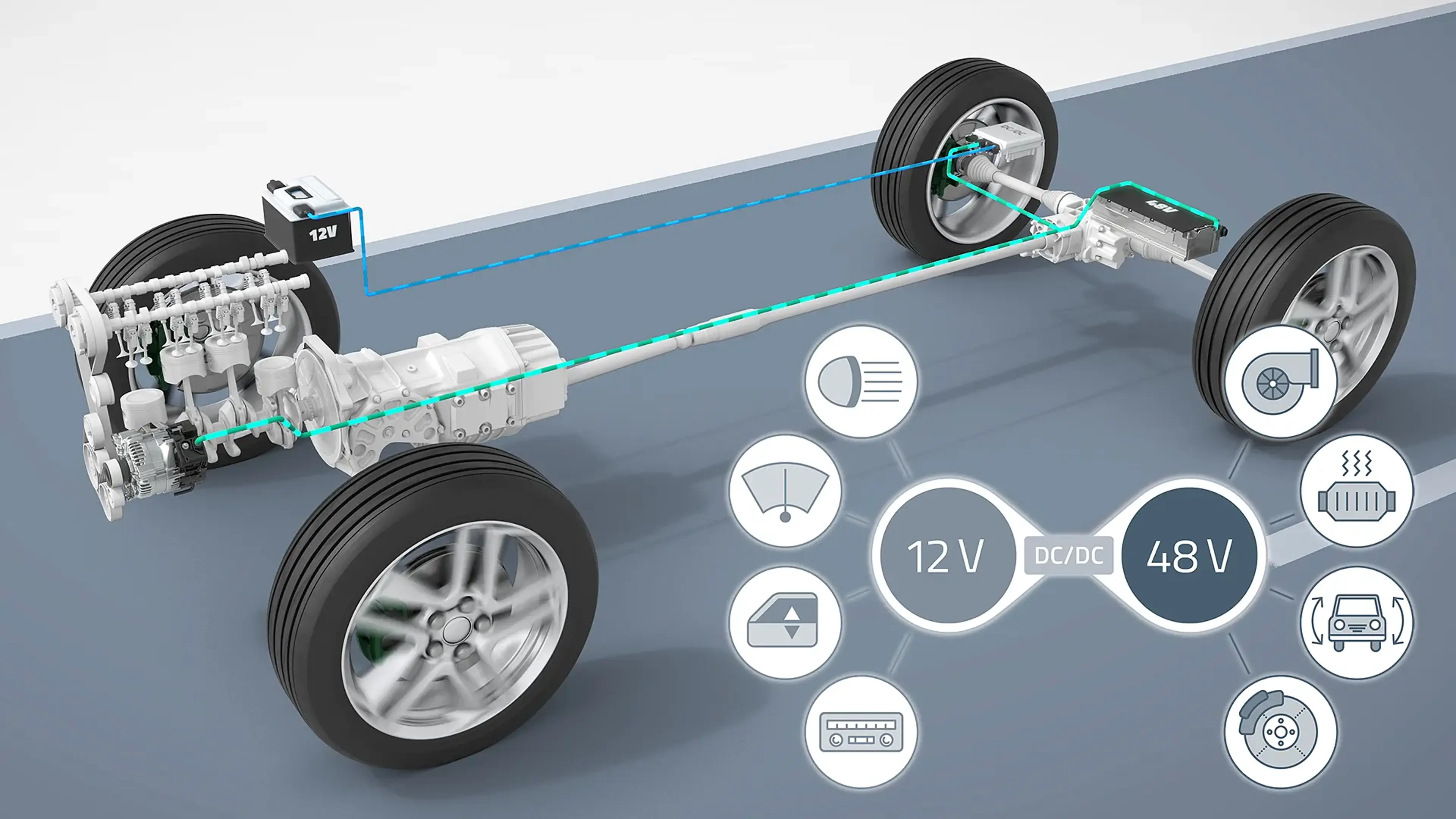

What is the benefit of the 48V on-board electric system? Does it replace the 12V on-board electric

The number of electrical consumers in cars today is much higher than it used to exist. Safety and comfort features such as active bike break or windshield heaters are just as energy-hungry equally high-performance pumps or turbochargers.

Due to the 4 times higher voltage level, a 48V motorcar can recuperate and significantly more than kinetic energy. Information technology then reliably supplies loftier-performance consumers and enables additional driving functions such as comfort start, heave and coasting. At the same time, 48V is a low enough to be not-hazardous to humans. In contrast to high-voltage systems, the 48V on-board electric system therefore has no special rubber requirements.

A 48V mild hybrid actually has two electrical systems. The conventional 12V system continues to supply all low-voltage consumers, such equally the radio, headlights, or window regulators. Not switching these components to a different voltage level results in less complication associated with arrangement integration. A DC/DC converter connects the two electrical systems – the recuperated braking energy can therefore as well supply the 12V electrical system.

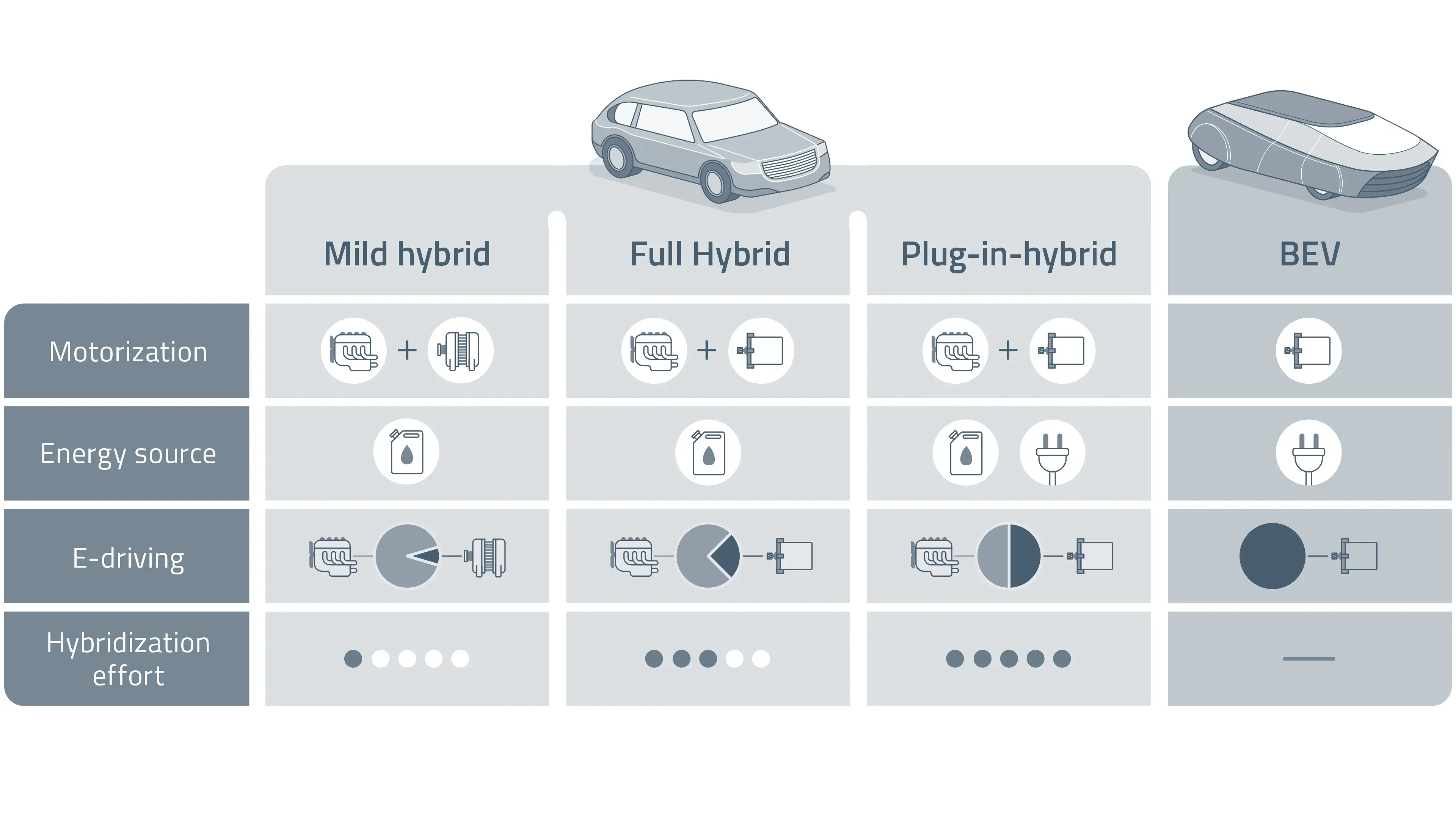

Comparison of technologies: What is the difference between a mild hybrid, full hybrid, plug-in hybrid and an electric

All these drive concepts accept an e-motor on board – but they differ especially in terms of primary free energy source, voltage level, and electric driving functions.

Mild-Hybrid

With balmy hybrids, the main drive is the combustion engine. The e-machine primarily serves to meliorate efficiency: Braking energy is recovered, stored in a small 48V battery (~0.five – 1 kWh), and used for additional torque and to supply the on-lath electrical system. This saves xv-25% of fuel consumption, depending on the topology. Purely electric driving is non possible at all or merely with severe restrictions.

Total-Hybrid

The full hybrid is based on the same principle. Energy is only supplied to the system externally via fuel, while the e-motor recuperates kinetic energy during braking and makes it available over again afterward. The departure: Full hybrids ordinarily operate on a loftier-voltage basis and have a larger battery. Security requirements and system costs are therefore significantly higher. On the plus side, even more energy tin can be recovered and stored, and short distances tin can be driven purely with the due east-motor.

Plug-in-Hybrid

A plug-in hybrid has 2 full-fledged drives – an internal combustion engine and a high-voltage electrical motor. This “double motorization” and the larger battery (often effectually 10kWh) add costs and weight. In return, purely electric driving is commonly possible for around twoscore-60 km, and the combustion engine is theoretically simply necessary for cross-country travel. The bombardment is charged via a socket, such as the household mains.

East-Auto (BEV)

The battery-powered electric vehicle (BEV) does not demand an internal combustion engine at all. It does, however, crave significantly larger batteries – around 20kWh of battery capacity per 100km, depending on the model. Here, also, charging takes place via the home power socket – or at the growing network of public charging stations

There is currently no single best choice for every consumer – the differences are too significant in terms of personal needs (due east.m., pure metropolis machine vs. professional commuter) and regional requirements (especially with regard to the charging infrastructure and the share of renewable free energy in the electricity mix). In the long term, the transformation of individual mobility is clearly moving toward BEVs; however, mild hybrid vehicles in detail tin can still forestall a lot of unnecessary CO2

emissions on this journey.

For which types of vehicles can 48V be

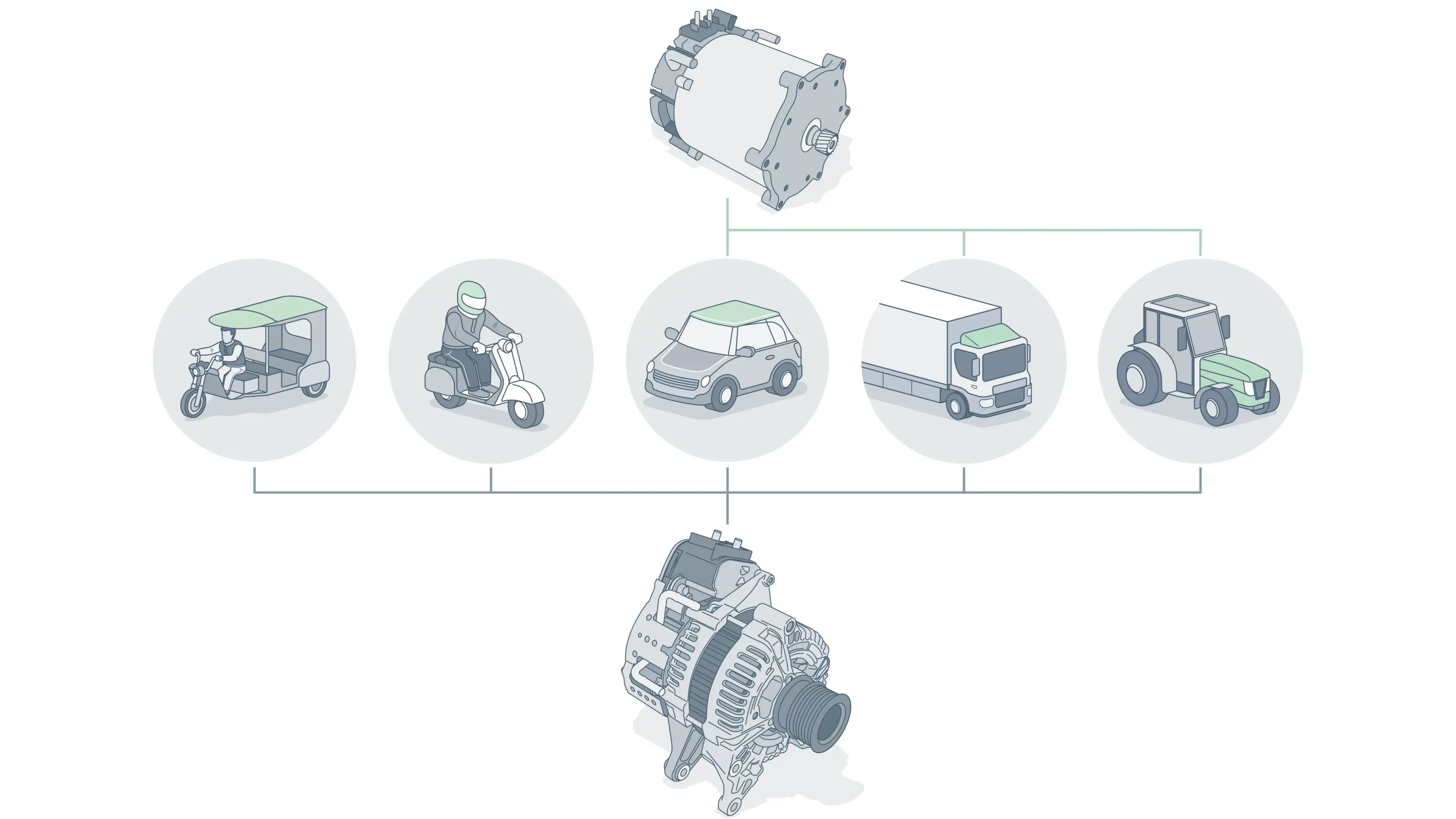

Combining a powerful e-motor with low safety requirements makes 48V machines suitable for a broad range of applications beyond mild hybrid applications.

In addition to the production portfolios of car manufacturers, 48V machines increasingly establish themselves as the principal bulldoze for low-cal electric vehicles. These applications range from east-scooters like the Schwalbe to electric rickshaws and minivans in India.

In passenger cars, too, 48V tin do more than than but mild hybridization. E-machines tin be scaled accordingly to deliver sufficient ability to drive 48V total hybrids or even compact 48V electrical vehicles. For example, putting two EM one.25s on the rear axle could accomplish this.

In the commercial vehicle sector, 48V machines are also opening upward new possibilities – from the start-stop function in light trucks to the mild hybridization of heavy trucks. 48V systems as well create new benefits and opportunities to reduce emissions in various off-road applications such as riding mowers.

2 and three-wheelers can be fully electrified with a 48V BRM, for example.

What makes mild hybridization interesting for manufacturers as

48V integrates iii aspects that are very attractive for automobile manufacturers, specially in combination: Meaning reduction of CO2

emissions, marketable benefits for the end consumer, and cost-constructive integration into existing vehicle platforms.

Increasingly stringent COii

limits are putting pressure on manufacturers to brand their vehicles ever more efficient. The systematic introduction of 48V hybrids beyond the portfolio tin can reduce fleet consumption quickly and effectively. It also makes it easier to meet emissions standards such as Euro7 in the future – on the 1 manus due to lower fuel consumption, but besides because the 48V on-board electrical organisation can preheat the catalytic converter during cold starts, and thus reduce emission spikes.

At the same time, with its benefits for the driver, 48V has become and boosted purchase incentive. Customers are wooed explicitly with the lower consumption and additional features such as condolement start or boost.

The mechanical integration effort is very manageable. A 48V machine can hands supersede the conventional generator in its installation place on the belt with a depression price impact in virtually all existing vehicle platforms. The 48V hybrid system is not only economical for the customer – information technology tin as well save costs for the manufacturer by fugitive possible punishment payments. In the EU, for instance, an easy-to-achieve saving of 10g CO2

per km through balmy hybridization corresponds to an avoided penalisation payment of € 950.00 – substantially roofing the system costs for a P0 solution.

What 48V solutions does SEG Automotive

SEG Automotive develops products for all powertrain architectures – regardless of whether the free energy comes from fuel, battery, or hydrogen. Our goal is always the same: to make the vehicle equally efficient as possible. Our robust solutions thus accelerate the shift to more than efficient combustion engines, electric vehicles and climate-neutral mobility.

Specifically for 48V, nosotros offering three different product families for a diverseness of applications – depending on the client’s needs, SEG Automotive provides these solutions as a complete package with electronics and software or as individual components:

What career opportunities are there in SEG Automotive’s

The complication of cars has increased speedily in contempo years, and not just considering of autonomous driving functions. As a result, our 48V and electrification products are backed by closely integrated teams for hardware, software, electronics, testing and manufacturing. From validation, prototyping and procedure development to coding and quality assurance, we offer exciting job profiles for engineers, software developers, logistics specialists, and more. See our Task Portal for more than information.

Source: https://www.seg-automotive.com/48v/mild-hybrid-technology/

TeknoHo.com Trusted Information and Education News Media

TeknoHo.com Trusted Information and Education News Media